Application: Finished products protection, including glass, touch screen components and ITO film products.

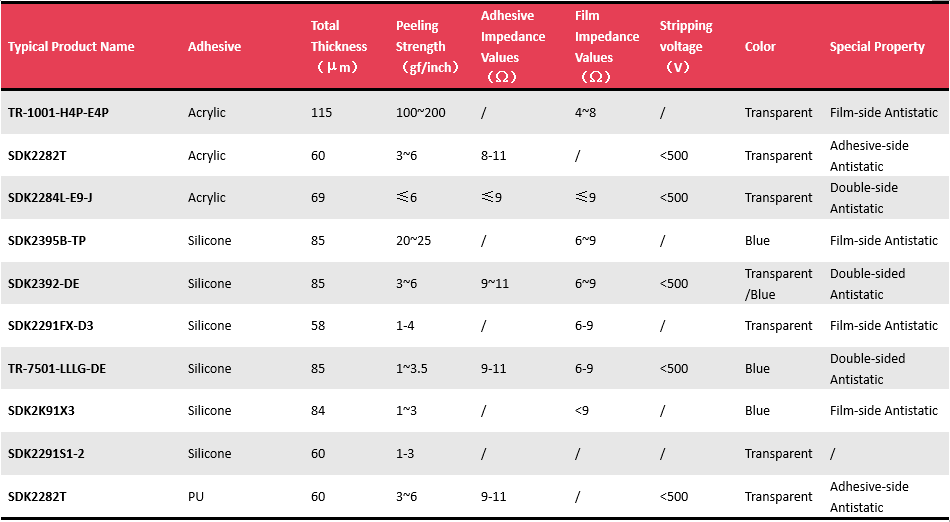

Antistatic Protective Film

• Coating in Class 1000 clean room,

• Excellent antistatic ability, stable bonding strength and weather resistance performance,

• Customized stripping voltage, adhesive strength and antistatic coating layer

• Film tearing voltage of some products can be less than 500V.

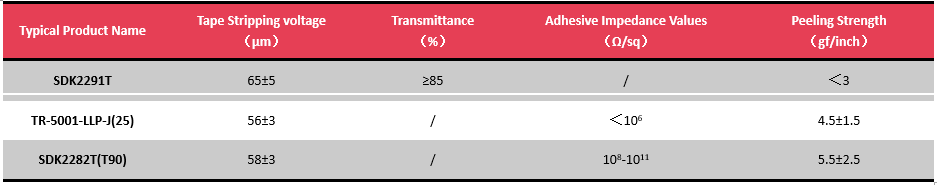

Application: Protection of glass, touch panel components, ITO film products, as well as CPI die-cutting process.

PU Protective Film

• Excellent outgassing performance, stable viscosity,

Printable functional protective material

• Special hard coating treatment would not be easily scratched and could be recoated with printable ink.

• The adhesive layer owns antistatic function to avoid electrostatic damage to components as well as dust.

• The adhesive layer has automatic adhesion to glass surface with good outgassing performance to avid bubble.

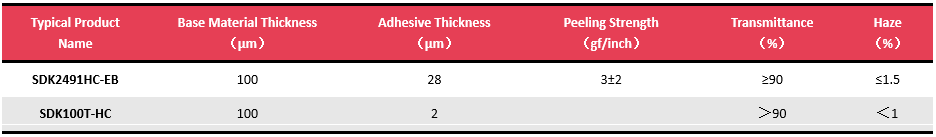

Application: Display Screen Packaging Protection

High Transmittance HC Protective Film

• Optical PET substrate, coating in class 1000 clean room coating,• The adhesive layer has automatic adhesion to glass surface with good outgassing performance to avid bubble.

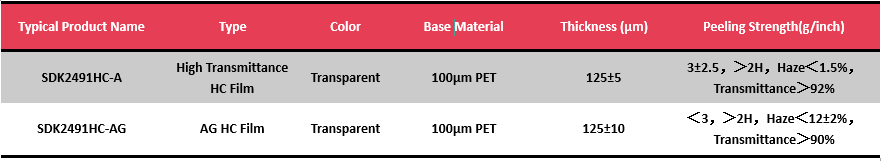

AG HC Protective Film

• Special AG + HC treatment with anti-glare effect of matt surface,

Jiangsu Sidike New Materials Science and Technology Co., Ltd.

Add: No.6 Shuangyang Road, Sihong Economic Development Area, Jiangsu Province, P. R. China

Hotline:+86 0527-8989 8333

Email:sales@sidike.com

official account